Product Description

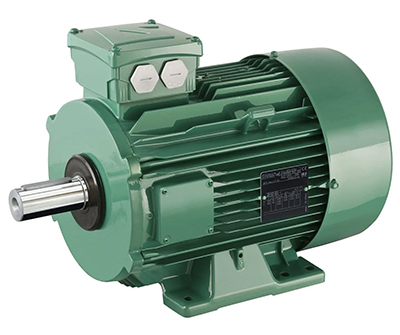

GS High Torque Long Life 40W 90mm AC Induction Gear Motor

1. Light weight, small dimension and simple installation;

2. Wide speed ranges and high torque;

3. Low noise and high efficiency;

4. Stable and safe,long lifetime;

5. Multi-structure, various assembling methods;

6. One-stop solution with speed controller, driver, encoder, brake and transformor available.

Product Picture

Speciafication

Motor Characteristics

| Motor Model | Specs | Output power | Voltage | Frequency | Current | Starting Torque | Rated Torque | Rated Speed | Capacitor/Ve |

| W | V | Hz | A | mN.m | mN.m | r/min | μF/VAC | ||

| GS5IK40GN-C GS5IK40A-C |

Induction | 40 | 1-phase 220 |

50 | 0.35 | 367 | 294 | 1300 | 2.5/450 |

| 60 | 0.33 | 307 | 246 | 1550 | 2.5/450 | ||||

| GS5RK40GN-C GS5RK40A-C |

Reversible 30min |

50 | 0.38 | 367 | 294 | 1300 | 3.0/450 | ||

| 60 | 0.4 | 307 | 246 | 1550 | 3.0/450 | ||||

| GS5IK40GN-A GS5IK40A-A |

Induction | 40 | 1-phase 110 |

50 | 0.70 | 367 | 294 | 1300 | 10/250 |

| 60 | 0.72 | 307 | 246 | 1550 | 10/250 | ||||

| GS5RK40GN-A GS5RK40A-A |

Reversible 30min |

50 | 0.76 | 367 | 294 | 1300 | 12/250 | ||

| 60 | 0.80 | 307 | 246 | 1550 | 12/250 | ||||

| GS5IK40GN-U GS5IK40A-U |

— | 40 | 3-phase 380 |

50 | 0.24 | 367 | 294 | 1300 | — |

| 60 | 0.22 | 307 | 246 | 1550 | — | ||||

| GS5IK40GN-S GS5IK40A-S |

— | 40 | 3-phase 220 |

50 | 0.4 | 367 | 294 | 1300 | — |

| 60 | 0.4 | 307 | 246 | 1550 | — |

Allowable load for the gear motor

| Geared-down parameter |

Sycchronous speed r/min |

500 | 300 | 250 | 200 | 150 | 120 | 100 | 75 | 60 | 50 | 40 | 35 | 30 | 25 | 20 | 15 | 12 | 10 | 8 | 7 | 6 | 5 | 3 | |

| Ratio i | 3 | 5 | 6 | 7.5 | 10 | 12.5 | 15 | 20 | 25 | 30 | 36 | 40 | 50 | 60 | 75 | 100 | 120 | 150 | 180 | 200 | 250 | 300 | 500 | ||

| Max allowable load | 40W | N.m | 0.72 | 1.18 | 1.43 | 1.77 | 2.4 | 2.94 | 3.53 | 4.28 | 5 | 6.24 | 7.7 | 8.57 | 9.64 | 9.81 | |||||||||

Note:

If this model is not what you want, please freely tell us about your requirement. We will provide you with a suitable motor solution and price soon.

Dimension Drawings

Product Pictures

Packing & Delivery

Company Overview

About Greensky Power

HISTORY: Greensky is a mechanical brand of CHINAMFG Power Co., Ltd. With over 10 years’ mechanical anufacturing experiences, CHINAMFG Power always strictly stands on the principle of Best Customer Satisfaction.

QUALITY: Material Inspection, Production Control, Finished Goods Test, Pre-dellivery Inspection

MISSION: “Once and forever” is our goal to serve customers in the world. Once we do business with customer, we will do business forever.

MARKET : 30 different countries, mainly Germany, Austria, Japan, USA and Middle-East.

DELIVERY : 100% on-time delivery Guaranteed.

SERVICES : Fast response in English, German, Japanese and Chinese languages.

OEM : Customized orders are welcome at CHINAMFG Power.

Exhibitions

Certificates

FAQ

1 Q: What’s your MOQ for each model?

A: 1unit is ok for sample testing

2 Q: What about your warranty for your gear motors?

A: One year.

3 Q: Do you provide OEM service with customer-logo?

A: Yes, we could do OEM orders, but we mainly focus on our own brand.

4 Q: How about your payment terms ?

A: TT, western union and paypal. 100% payment in advanced for orders less $5,000. 30% deposit and balance before delivery for orders over $5,000.

5 Q: How about your packing ?

A: Carton, Plywood case. If you need more, we can pack all goods with pallet.

6 Q: What information should be given, if I buy gear motors from you?

A: Rated power, gearbox ratio, input speed, mounting position. More details, better!

7 Q: How do you deliver the gear motor?

A: We will compare and choose the most suitable ways of delivery by sea, air or express courier.

We hope you will enjoy cooperating with us.We hope you enjoy cooperating with us.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Pellet Boiler, Industrial, Machinery |

|---|---|

| Speed: | Low Speed |

| Number of Stator: | 1-Phase or 3-Phase |

| Function: | Driving |

| Casing Protection: | Protection Type |

| Number of Poles: | 4 |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

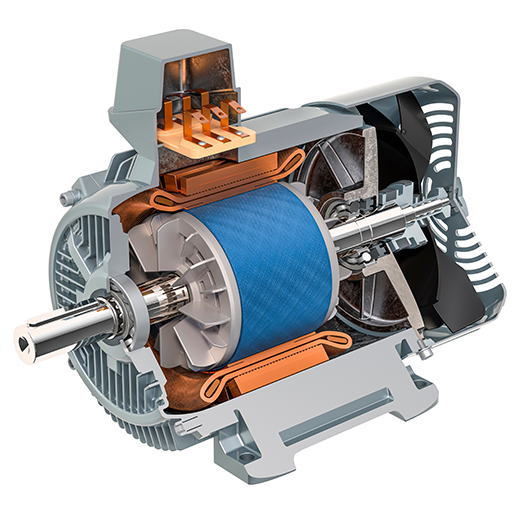

How do manufacturers ensure the quality and reliability of induction motors?

Manufacturers employ several measures and quality control processes to ensure the quality and reliability of induction motors. Here are some key steps taken by manufacturers:

- Design and Engineering:

- Manufacturers invest significant resources in the design and engineering of induction motors.

- Experienced engineers use advanced computer-aided design (CAD) software to develop motor designs that meet performance specifications and industry standards.

- Design considerations include efficient cooling, optimal winding configurations, and robust mechanical construction.

- Material Selection:

- Manufacturers carefully select high-quality materials that meet or exceed industry standards.

- They use premium-grade electrical steel laminations for the motor core to minimize energy losses and maximize efficiency.

- Copper or aluminum conductors with appropriate insulation are chosen for the motor windings to ensure reliable electrical performance.

- Stringent Manufacturing Processes:

- Manufacturers follow stringent manufacturing processes to ensure consistency and quality throughout production.

- They employ advanced machinery and automation to achieve precise manufacturing tolerances and reduce human error.

- Quality control checks are performed at various stages of the manufacturing process to identify and rectify any issues.

- Testing and Inspection:

- Induction motors undergo rigorous testing and inspection procedures to verify their performance and reliability.

- Manufacturers conduct various tests, such as electrical tests, mechanical tests, insulation tests, and performance tests.

- These tests ensure that the motors meet or exceed specified parameters for voltage, current, power factor, efficiency, torque, and speed.

- Inspection processes involve visual inspections, dimensional checks, and verification of critical components.

- Certifications and Compliance:

- Reputable manufacturers ensure that their induction motors comply with relevant industry standards and regulations.

- They obtain certifications, such as ISO 9001 for quality management systems, and adhere to specific standards like IEC (International Electrotechnical Commission) or NEMA (National Electrical Manufacturers Association).

- Certifications and compliance demonstrate the manufacturer’s commitment to producing high-quality and reliable products.

- Customer Feedback and Continuous Improvement:

- Manufacturers value customer feedback and use it as a valuable source of information for continuous improvement.

- They actively engage with customers to understand their needs and address any concerns or issues promptly.

- Feedback helps manufacturers refine their designs, manufacturing processes, and quality control measures to enhance the overall quality and reliability of their induction motors.

By implementing these measures, manufacturers strive to ensure that their induction motors meet the highest standards of quality and reliability. Continuous improvement and adherence to industry best practices enable manufacturers to deliver products that perform consistently and reliably in a wide range of applications.

How do induction motors handle variations in load, speed, and torque?

Induction motors are designed to handle variations in load, speed, and torque through their inherent characteristics and control mechanisms. Here’s a detailed explanation of how induction motors handle these variations:

Variations in Load:

Induction motors can effectively handle variations in load due to their unique operating principle. These motors rely on electromagnetic induction to generate a rotating magnetic field, which interacts with the rotor to produce torque. When the load on the motor changes, the motor adjusts to maintain the required torque. Here’s how induction motors handle load variations:

- Slip: Induction motors operate at a certain slip, which is the difference between the synchronous speed and the actual rotor speed. The slip allows the motor to maintain torque when the load changes. As the load increases, the slip also increases, enabling the motor to deliver more torque.

- Torque-Slip Characteristics: Induction motors exhibit a characteristic known as torque-slip curve. This curve shows the relationship between torque and slip. The torque-slip curve demonstrates that the motor can deliver high torque at low slip (during startup or heavy loads) and lower torque at higher slip (during light loads).

- Stable Operation: Induction motors are designed to operate with a certain margin between the available torque and the torque required by the load. This margin allows the motor to accommodate variations in load while maintaining stable and continuous operation.

Variations in Speed:

Induction motors can handle variations in speed through the following mechanisms:

- Synchronous Speed: The synchronous speed of an induction motor is determined by the frequency of the power supply and the number of poles in the motor. It represents the speed at which the rotating magnetic field would move if there were no slip. However, the actual speed of the rotor is always slightly less than the synchronous speed due to slip.

- Fixed Speed: Standard induction motors are designed to operate at a fixed speed, which is determined by the power supply frequency and the number of poles. Therefore, they are often referred to as “constant-speed motors.” These motors are suitable for applications where a consistent speed is required, such as in many industrial processes.

- Variable Speed: To handle variations in speed, induction motors can be equipped with additional control mechanisms. One common method is to use a variable frequency drive (VFD). A VFD allows precise control of the motor’s speed by adjusting the frequency and voltage supplied to the motor. By varying the frequency and voltage, the motor’s speed can be adjusted to match the requirements of the application.

- Inertia: Induction motors have a certain amount of inertia, which provides stability and helps them resist sudden changes in speed. The inertia allows the motor to maintain a relatively constant speed even when the load changes momentarily.

Variations in Torque:

Induction motors can handle variations in torque through their inherent design and operating characteristics:

- Starting Torque: Induction motors can provide high starting torque to overcome the inertia of the load during startup. This starting torque allows the motor to start and accelerate the load smoothly.

- Full-Load Torque: Induction motors are designed to deliver the rated full-load torque required by the application. The full-load torque ensures that the motor can handle the normal operating conditions and provide the necessary power to drive the load efficiently.

- Overload Capacity: Induction motors often have an overload capacity that allows them to handle temporary increases in torque beyond their rated full-load torque. This overload capacity is useful for applications that may experience occasional high torque demands or temporary overloads.

- Controlled Torque: By using control methods such as VFDs, induction motors can have their torque adjusted and controlled precisely based on the requirements of the application. This allows for flexibility in matching the motor’s torque output to the load’s needs.

In conclusion, induction motors handle variations in load, speed, and torque through their inherent characteristics such as slip, torque-slip curve, fixed speed, and the use of additional control mechanisms like variable frequency drives. These features enable induction motors to provide stable operation, adjust their speed, and deliver the required torque to meet the demands of various applications.

How do induction motors differ from other types of electric motors?

Induction motors differ from other types of electric motors in several ways. Here’s a detailed explanation of the key differences:

- Operating Principle:

- Induction motors operate based on the principle of electromagnetic induction, where a rotating magnetic field induced by the stator windings interacts with the rotor conductors to produce torque.

- In contrast, other types of electric motors, such as DC motors, synchronous motors, and stepper motors, operate on different principles and have distinct mechanisms for generating motion.

- Power Supply:

- Induction motors typically operate on AC (alternating current) power supply. The stator windings are connected to an AC power source, which produces a rotating magnetic field.

- On the other hand, DC motors require a DC power supply, and synchronous motors may operate on either AC or DC power supply, depending on their design.

- Speed Control:

- Induction motors have a fixed speed determined by the frequency of the AC power supply and the number of poles in the motor. The speed can be adjusted to some extent by changing the supply frequency or using variable frequency drives (VFDs).

- DC motors, on the other hand, offer precise speed control by adjusting the voltage applied to the motor armature.

- Synchronous motors can operate at a fixed speed determined by the frequency of the AC power supply, but they can also be controlled using specialized techniques such as field weakening or using electronic drives.

- Stepper motors operate in discrete steps, allowing precise control of position and speed.

- Construction:

- Induction motors are typically constructed with a squirrel cage rotor, which consists of short-circuited conductive bars or loops. The rotor construction makes them simple, robust, and suitable for high-speed applications.

- Other types of motors may have different rotor constructions, such as wound rotors in some AC motors or permanent magnets in brushless DC motors.

- Starting Mechanism:

- Induction motors are self-starting, meaning they can start without the need for additional starting mechanisms. The rotating magnetic field generated by the stator windings induces voltage and current in the rotor, enabling the motor to start rotating.

- Some other types of motors, such as DC motors, require external starting mechanisms like starting resistors or electronic controls to initiate rotation.

- Efficiency and Maintenance:

- Induction motors are known for their high efficiency and low maintenance requirements. They have a simple construction with no brushes or commutators, which reduces wear and eliminates the need for regular maintenance.

- Other types of motors, such as brushed DC motors, may require brush replacement and periodic maintenance.

These are some of the main differences between induction motors and other types of electric motors. Each type of motor has its advantages, disadvantages, and specific applications, depending on the requirements of the system or industry where they are used.

editor by CX 2024-03-28