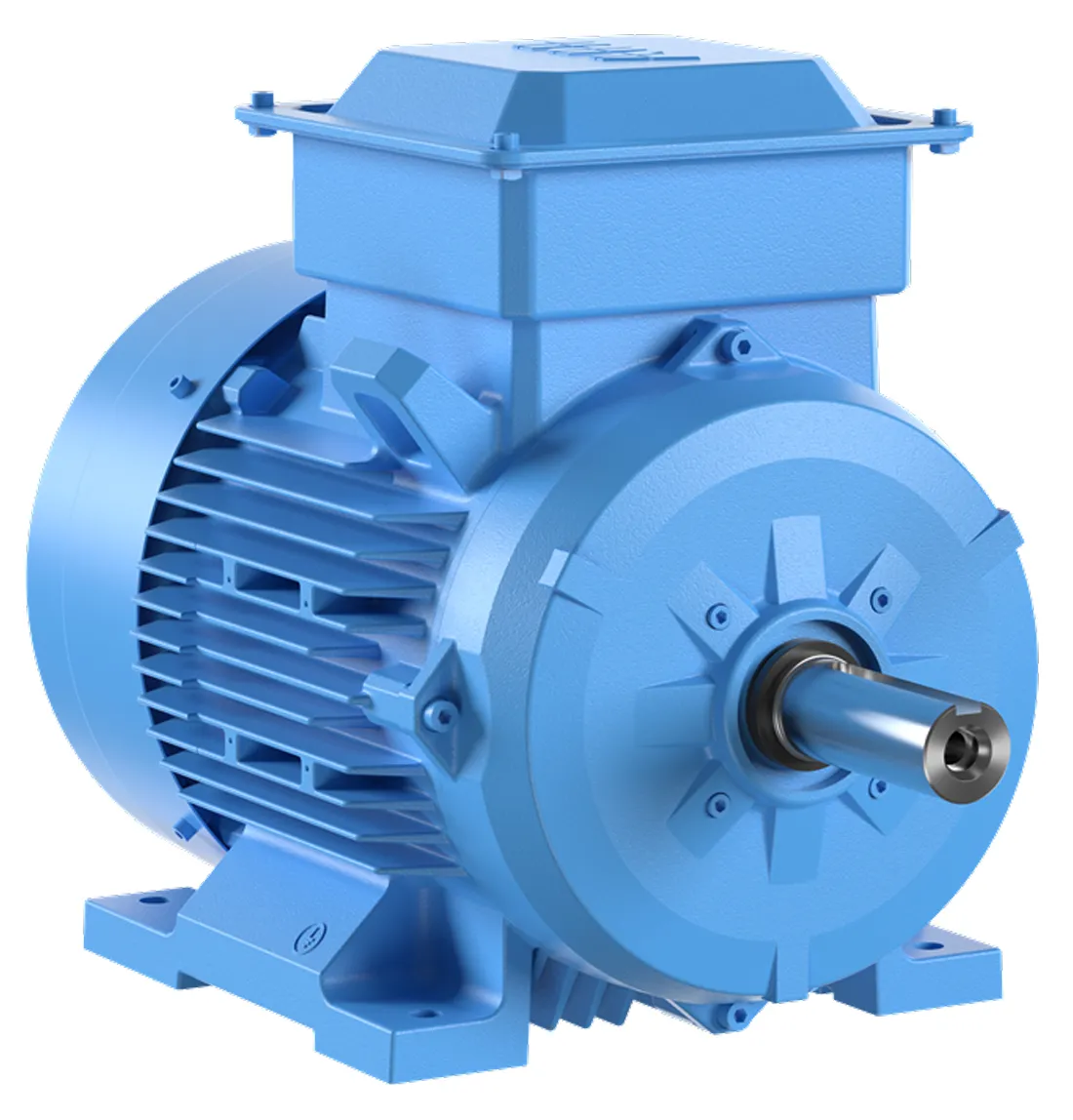

Product Description

Product Information

|

Specifications |

|

|

Rated voltage:380V |

Power: 0.75KW-250KW |

|

Rotating speed:2p,4p,6p |

Weight: 19KG-2092KG |

|

Duty/Rating:IP55 |

Insulation class: F |

|

Cooling type:IC0041 |

Protection class: S1 |

|

Ambient temperature:-15ºC~+40ºC |

Energy efficiency: 2 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Operating Speed: | Low Speed |

| Number of Stator: | Three-Phase |

| Species: | Air Motor |

| Rotor Structure: | Squirrel-Cage |

| Casing Protection: | Protection Type |

| Samples: |

US$ 310/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can induction motors be adapted for use in both residential and industrial settings?

Yes, induction motors can be adapted for use in both residential and industrial settings. Here’s a detailed explanation:

Induction motors are versatile and widely used in various applications due to their robustness, efficiency, and reliability. They can be found in both residential and industrial environments, albeit with some variations in design and performance characteristics.

Residential Use:

- In residential settings, induction motors are commonly found in household appliances such as refrigerators, air conditioners, washing machines, fans, and pumps.

- These motors are typically smaller in size and power compared to their industrial counterparts, as they are designed to meet the specific requirements of residential applications.

- Residential induction motors are often single-phase motors, as most residential electrical systems are single-phase.

- They are designed for easy installation, low noise operation, and energy efficiency to meet the demands of residential users.

- These motors are typically optimized for specific applications, such as providing the necessary torque and speed control for appliances like washing machines or maintaining the desired temperature in air conditioners.

Industrial Use:

- In industrial settings, induction motors are widely employed in a wide range of applications, including pumps, compressors, conveyor systems, machine tools, fans, blowers, and many more.

- Industrial induction motors are available in a wide range of power ratings and sizes, allowing them to meet the diverse needs of industrial processes.

- They are often three-phase motors, as most industrial electrical systems utilize three-phase power distribution.

- Industrial motors are designed to handle heavy loads, operate under harsh conditions, and provide high levels of reliability and durability.

- These motors can be adapted for specific industrial requirements, such as motors with explosion-proof enclosures for hazardous environments or motors with enhanced protection against dust and moisture.

- Industrial induction motors may also incorporate advanced control features, such as variable frequency drives (VFDs), to enable precise speed control, energy savings, and integration into automated industrial systems.

Adaptability:

While there are differences in design and performance characteristics between residential and industrial induction motors, the fundamental principles and technology behind them remain the same. Induction motors can be adapted to meet the specific needs of both residential and industrial settings by adjusting factors such as size, power rating, number of phases, construction materials, and control features.

Manufacturers cater to the distinct requirements of residential and industrial users by producing a wide variety of induction motors tailored to each application. This adaptability allows for the efficient use of induction motors in diverse settings, from small-scale residential applications to large-scale industrial operations.

In conclusion, induction motors can be successfully adapted for use in both residential and industrial settings by considering the specific requirements and optimizing the motor’s design and performance characteristics accordingly.

What advancements in induction motor technology have improved energy efficiency?

Advancements in induction motor technology have led to significant improvements in energy efficiency. These advancements have been driven by various factors, including stricter energy regulations, environmental concerns, and the need for cost-effective operation. Here’s a detailed explanation of the key advancements that have improved energy efficiency in induction motors:

High-Efficiency Motor Designs:

Manufacturers have developed high-efficiency designs for induction motors that minimize energy losses and maximize output. These designs incorporate improved core materials, optimized winding configurations, and reduced air gaps, resulting in reduced core losses and improved magnetic coupling. High-efficiency motor designs can achieve higher efficiency levels compared to traditional motor designs, leading to energy savings in various applications.

Premium Efficiency Standards:

Introduction of premium efficiency standards by regulatory bodies and organizations has played a significant role in improving the energy efficiency of induction motors. These standards define minimum efficiency requirements for motors in specific power ranges. Induction motors meeting premium efficiency standards are designed to operate at higher efficiency levels, reducing energy consumption and promoting the adoption of energy-efficient motor technologies.

Improved Insulation Systems:

Advancements in insulation materials and systems have contributed to improved energy efficiency in induction motors. Enhanced insulation systems help reduce electrical losses and improve the motor’s overall efficiency. Newer insulation materials offer better thermal conductivity, improved dielectric strength, and increased resistance to electrical stress, resulting in reduced heat generation and improved motor performance.

Variable Frequency Drives (VFDs):

The widespread adoption of Variable Frequency Drives (VFDs) has greatly enhanced the energy efficiency of induction motors. VFDs enable precise control of motor speed by adjusting the frequency and voltage supplied to the motor. By matching the motor’s speed to the actual load requirements, VFDs eliminate the energy wastage associated with fixed-speed motors running at constant speed. VFDs also provide additional features such as soft-start and dynamic braking, further improving energy efficiency.

Advanced Motor Control Techniques:

Advanced motor control techniques, such as vector control or field-oriented control (FOC), have been developed to improve the energy efficiency of induction motors. These control techniques allow for precise control of motor torque and speed, even under varying load conditions. By optimizing motor control algorithms and adjusting parameters in real-time, these techniques minimize energy losses and maximize motor efficiency, particularly in applications with fluctuating loads.

Integration with Automation Systems:

Integration of induction motors with advanced control systems and automation technologies has also contributed to improved energy efficiency. By connecting motors to Programmable Logic Controllers (PLCs), Supervisory Control and Data Acquisition (SCADA) systems, or Industrial Internet of Things (IIoT) platforms, manufacturers can implement energy management strategies, perform real-time monitoring, and optimize motor operation based on actual demand. This integration enables energy-efficient operation and reduces unnecessary energy consumption.

Efficient Cooling Systems:

Advancements in cooling systems for induction motors have also played a role in improving energy efficiency. Efficient cooling mechanisms, such as improved fan designs, optimized airflow paths, and intelligent temperature monitoring systems, help maintain the motor’s temperature within the optimal range. By preventing overheating and minimizing thermal losses, these cooling systems contribute to improved motor efficiency and extended motor life.

In conclusion, several advancements in induction motor technology have led to improved energy efficiency. High-efficiency motor designs, premium efficiency standards, improved insulation systems, Variable Frequency Drives (VFDs), advanced motor control techniques, integration with automation systems, and efficient cooling systems are among the key advancements that have significantly enhanced the energy efficiency of induction motors. These advancements promote sustainable and cost-effective operation, offering benefits such as reduced energy consumption, lower operating costs, and reduced environmental impact.

How does an induction motor ensure efficient and reliable performance?

An induction motor is designed and engineered to ensure efficient and reliable performance. Here’s a detailed explanation of how an induction motor achieves these qualities:

- Robust Construction:

- Induction motors are built with robust construction techniques and materials to withstand the demands of various applications.

- The stator and rotor cores are typically made from laminated steel sheets, which reduce eddy current losses and improve magnetic flux efficiency.

- The rotor is often constructed as a squirrel cage, consisting of short-circuited conductive bars or loops, which enhances durability and eliminates the need for maintenance-prone components like brushes and commutators.

- Efficient Design:

- Induction motors are designed for high efficiency, which means they convert a significant portion of the electrical input power into useful mechanical power.

- The rotor design and the air gap between the rotor and stator are optimized to minimize energy losses and maximize torque production.

- The stator windings are carefully designed to produce a rotating magnetic field with minimal copper losses and magnetic flux leakage.

- Efficiency is further improved by using high-quality materials with low electrical resistance for the stator windings and rotor conductors.

- Self-Starting Capability:

- Induction motors have a self-starting capability, meaning they can start and accelerate to their operating speed without the need for additional starting mechanisms.

- When the motor is connected to an AC power supply, the rotating magnetic field generated by the stator windings induces voltage and current in the rotor, initiating rotation.

- This self-starting feature eliminates the need for complex and maintenance-prone starting mechanisms, resulting in a reliable and hassle-free motor operation.

- Low Maintenance:

- Induction motors are known for their low maintenance requirements.

- They do not have brushes or commutators that require regular replacement or servicing.

- The absence of these components reduces wear and maintenance costs, making induction motors highly reliable and cost-effective.

- Protection Mechanisms:

- Induction motors are equipped with various protection mechanisms to ensure safe and reliable operation.

- Thermal protection devices, such as thermal overload relays or thermistors, are used to monitor the motor’s temperature and prevent overheating.

- Overcurrent and short-circuit protection devices, such as circuit breakers or fuses, safeguard the motor against excessive current and electrical faults.

- Voltage and phase protection devices help protect the motor from voltage fluctuations and phase imbalances, which can cause damage or affect performance.

- Efficient Cooling:

- Induction motors are designed with effective cooling mechanisms to dissipate heat generated during operation.

- Fans or other cooling methods are employed to circulate air over the motor’s internal components, ensuring optimal operating temperatures.

- Proper cooling minimizes temperature rise, prevents insulation degradation, and extends the motor’s lifespan and performance.

- Quality Manufacturing:

- Induction motors are manufactured using quality control measures to ensure consistent performance and reliability.

- Manufacturers adhere to industry standards and conduct rigorous testing and inspection procedures during the production process.

- This attention to quality ensures that each motor meets the required specifications and performs reliably in various operating conditions.

By incorporating these features and design considerations, induction motors deliver efficient and reliable performance, making them a popular choice for a wide range of applications in industries and everyday use.

editor by CX 2024-04-29